engineering

We Help You Convert Your Concepts into Final Products

Concorde Works to Simplify the Design Engineering of Your Product

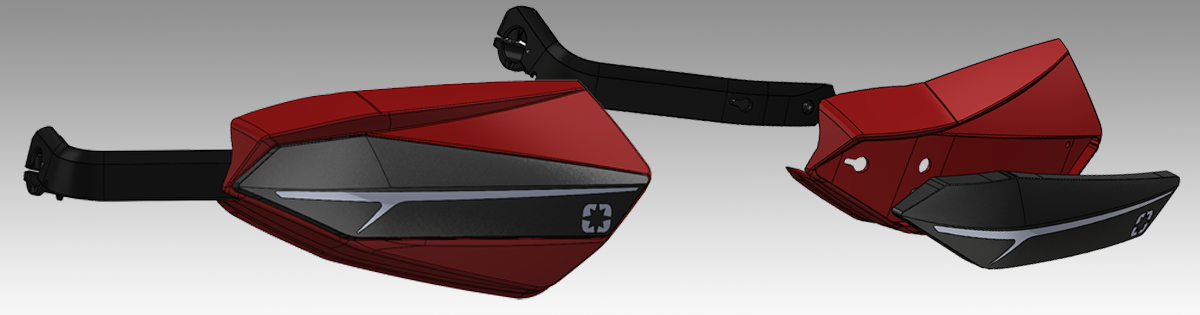

Precision Engineering: We Support the Journey to Convert Your Concept into a Manufacturing-ready Product

Precision product engineering is in our DNA: Our extensive experience and skills in SolidWorks present you with the benefit of

digitally optimizing your product in CAD to be certain your product is on track. With greater collaboration, you’ll be sure your

product moves through the engineering and DFM (design for manufacturing and manufacturability) analysis as rapidly as

possible.

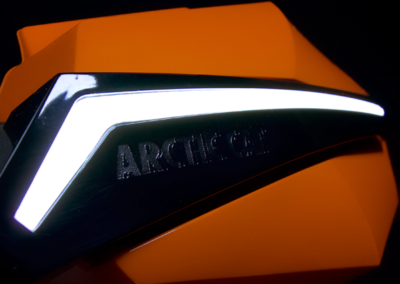

Electrical Engineering: We Develop A Wide Range of Electrical, Lighting Systems, and LED Fixtures

One of the things that sets us apart is the ability to develop single- and multi-function electrical and lighting systems,

supported by our extensive international manufacturing resources. There is no project we can’t tackle, providing you with a

flexible and wide range of electrical solutions for your products.

Concorde’s CAD (computer aided design) and technical systems are in place to work with most software file formats:

● SolidWorks assembly, part, drawing files, file conversion

● STP (STEP, standard for the exchange of product model data)

● IGS (IGES, initial graphics exchange specification)

● DXF (Drawing Interchange Format, or Drawing Exchange Format, developed by Autodesk)

● DWG (3D and 2D drawing format for various CAD packages, including AutoCAD)

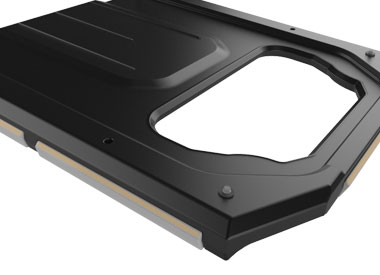

Tooling Expertise: We Develop Tools and Produce Your Custom-engineered Products

Tooling and fixtures are typical in the right-sized manufacturing process for your product, ranging:

● From highly complex, progressive tooling to manufacture integrated assemblies and robotic weldments

● To simple medium-to- high volume molds, die sets, castings, extrusions, and assembly tools and fixtures

● Inspection fixtures, in-process, go/no-go, and final audit fixtures, to support the product’s quality management plan.

Our process tooling examples include blow molding, injection molding, die casting, progressive metal stamping, plastic and

metal fabrication, CNC machining, and automated assembly, to name a few.

Concorde has the know-how:

● VA/VE (Value analysis/Value engineering)

● NPI (New product introduction)

● PPAP (Production part approval process documentation)

● P3 (Production prototype part)

● FAIR (First article inspection reporting)

Complete mechanical design services, and electrical design services are available for high volume potential products.